Our Engineering & Design division serves as the foundation of precision manufacturing at CD Engineering. Using advanced CAD/CAM systems, we design dies and forgings that ensure dimensional integrity and performance reliability.

CD Engineering houses a state-of-the-art Cutting Shop equipped with multiple bandsaw machines, including CNC-controlled band saws, circular saws, and advanced plasma cutting. This facility ensures the precise preparation of raw materials before they move to the forging stage. Raw materials are prepared in our Cutting Shop with high-precision saws to ensure accurate input dimensions for forging. Every cut billet is traceable and verified.

CD Engineering Forging Shop stands at the core of our manufacturing strength. Including Open, CNC, Die Forging, and Ring Rolling — and multiple robust power presses, the shop is built to deliver precision-forged components across diverse grades and specifications.

Each hammer is supported by a dedicated temperature-controlled or induction furnace, ensuring optimal forging temperatures specific to each material grade. For handling heavy-duty forgings, our facility is equipped with hydraulic chargers and manipulators, enabling efficient and safe movement of large forgings during high-temperature operations.

Run by experienced forge masters and backed by real-time monitoring and strict quality protocols, the shop ensures repeatability, structural integrity, and consistent output.

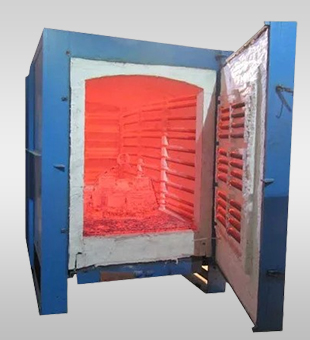

CD Engineering’s in-house Heat Treatment Shop is built to deliver precise mechanical properties across varied alloy grades. Our facility houses calibrated automatic and electric furnaces, capable of executing grade-specific thermal cycles under controlled atmospheres.

From normalization to solutionizing, every heat treatment process is carefully programmed to ensure uniform structural integrity, enhanced machinability, and compliance with global standards and customer specifications.

CD Engineering Machine Shop is equipped with a cutting-edge lineup of state-of-the-art machines, engineered to deliver unmatched precision and exceptional efficiency. We are capable of producing components with exacting tolerances and superior surface finishes, consistently meeting the most demanding global standards.

Each machine is supported by strict quality controls and full process documentation to ensure optimum performance and traceability.

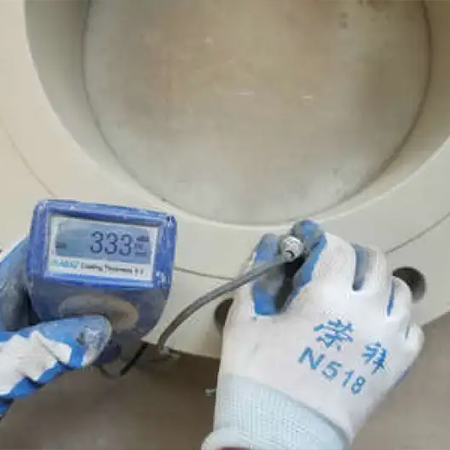

CD Engineering implements multiple quality checkpoints from raw‐material receipt through to final dispatch. Our QA team utilizes modern testing equipment to verify each component’s chemical, mechanical, and dimensional properties against standards and customer specifications. Every component undergoes layered inspections— spectrochemical analysis, PMI, dimensional and visual checks at every step—to guarantee uncompromised quality.

Our Quality Control Lab performs rigorous tests at each production stage, ensuring full compliance with international benchmarks. Some of our lab facilities include but not limited to:

With this comprehensive QA/QC framework, CD Engineering assures reliable, high‑integrity products for the most demanding applications.

CD Engineering’s Epoxy Shop delivers industry‑leading surface protection for forged components, combining advanced coating technologies with rigorous process control. Our epoxy and anti‑rust systems are engineered to exceed client specifications for corrosion resistance and durability.